Can our clients learn how to cut costs from cement projects we have completed? The answer is YES!

DO IT WELL ONCE is the only way to do it, and our clients are well aware of this.

This April, a team of four went to Wittekind Portland Cement Plant in Erwitte, Germany, for an urgent installation of SpeedBolt® anchors. This wasn't our first visit to this site; we had previously completed a SpeedBolt® installation there in 2019.

Our Rapid Arc Welding (RAW) team mobilized quickly to the site and headed directly to the Kiln upon arrival. The welding area was quite extensive, with numerous old anchors, significant deterioration, and holes that had been covered with plates later on.

The team split into day and night shifts. Old anchors were removed. While the SILICON team was busy with SpeedBolt® installation, the Wittekind Portland Cement team was installing the plates to cover the holes. Our team marked the surface to align anchors with the plates.

During installation, an additional order of anchors was placed and delivered the very next day! The job was completed successfully, and the customer was happy with the speed and quality of our work.

![]()

The cement plant of the future will operate with reduced costs, driven by digitalization and sustainability - key trends shaping the future of the cement industry.

Wittekind Portland Cement Plant understands that operational advancements are crucial. Technologies like Rapid Arc Welding and quality refractory anchors for cement plants not only save time but cuts the Turnaround and shutdown expenses.

Whether your kilns and mills need modernization or you are at the start of prefabrication, if you are looking for the right service contractor, SILICON’s full-service solution is built to cut your project’s costs by DOing IT WELL ONCE.

We can install refractory anchors in 100% of your units!

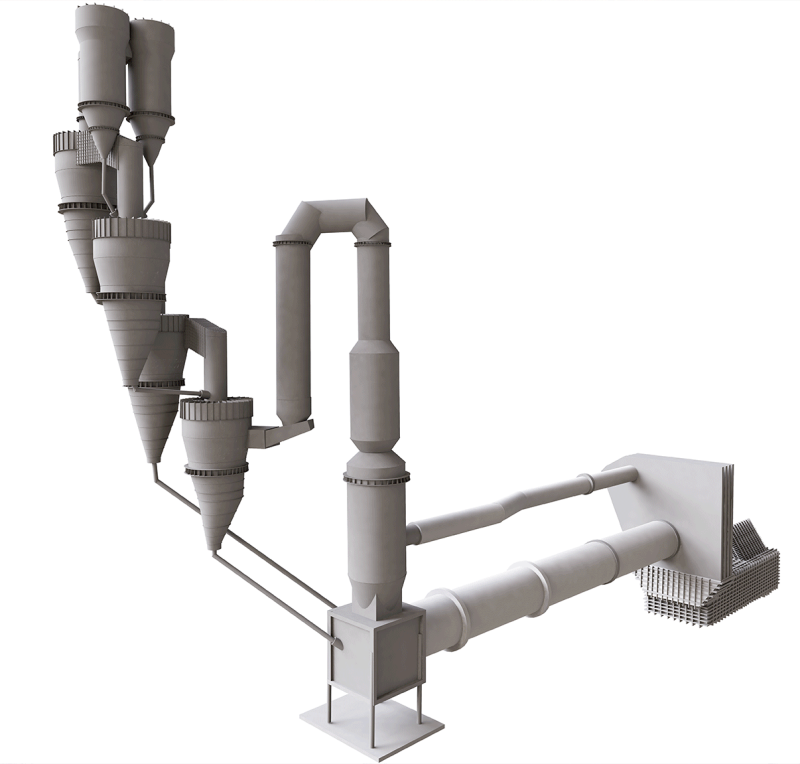

SpeedBolts® can be welded in the Rotary Kiln, Cooler, Pre-Heater Cyclones, Upper and Lower Cyclones. Our RAW-weldable SpeedClaw is perfect for Calciner, and SpeedCell® is ideal for Burner Pipes. We can even RAW weld CV anchors instead of CH2 anchors in the Area Ducts. Any hand-welded anchor can be adapted to Rapid Arc Welding.

SILICON is a leading expert in the refractory industry and your trusted advisor for all your refractory needs.

Click on the various components for more information.

In Pre-Heater Cyclones, the SpeedBolt® System can last 10+ years. Find out more about this moveable system:

C-10 Moveable anchors (SpeedBolt®)The SpeedBolt® system is used in Cyclones, which can last 10+ years. Find out more about this moveable system:

C-10 Moveable anchors (SpeedBolt®)Brick claws are used in the Calciner. SILICON has created the RAW weldable SpeedClaw. Find out more about this system:

B-03 Brick ClawsStress often arises in Rotary Kilns due to refractory movement. Explore the SILICON moveable SpeedBolt® System here to address this issue.

C-10 Moveable anchors (SpeedBolt®)Burner pipes see a lot of corrosion due to the intense heating process, the SILICON SpeedCell® solved this. Find out more:

C-11 SpeedCell®In the cooler, the SILICON SpeedBolt® system is used, which is a moveable anchoring system. Find out more about this solution:

C-10 Moveable anchors (SpeedBolt®)