The petrochemical industry is the cornerstone of contemporary society, fuelling industrial operations, heating households, and facilitating the movement of goods and individuals.

SILICON’s contribution lies in enabling refineries to reach unprecedented standards of safety and operational excellence through our refractory anchor solutions and RAW technology.

Over the course of numerous decades, the petrochemical industry has been dedicated to tackling a range of challenges linked to high-temperature processing vessels. A predominant contributor to these concerns has been the inadequate installation of hex metal, leading to eventual failures.

The quest for ever better performance led firstly to the SpeedCell® system which later evolved into the SpeedHex® 3 system. This is an ideal solution for all petrochemical refractory issues and we are ready to help you!

SILICON is dedicated to providing the petrochemical industry with a complete solution for refractory anchoring systems. Our goal is to ensure your operations run seamlessly during planned or unexpected Turnarounds.

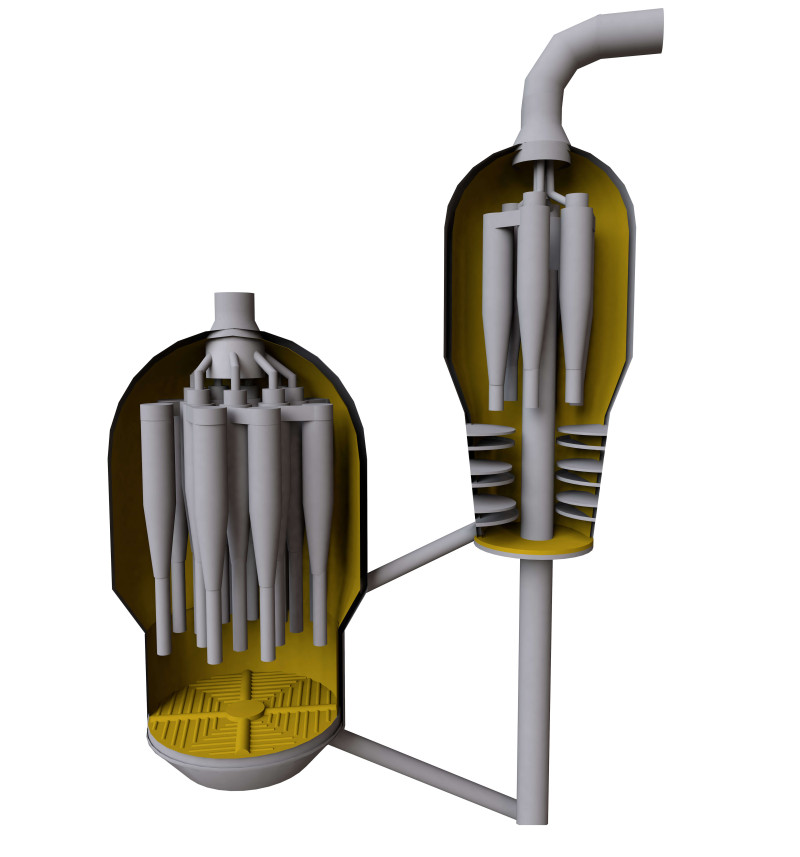

We have products for each component of an FCC unit, including the regenerator, cyclones, air grid, stripper, reactor, distillation tower, and riser.

Click on the various components for more information.

SpeedHex®3, which withstands heavy abrasion, is used in the Regenerator. The SpeedTab® is employed for edges and corners.

More: SpeedSeriesSpeedHex®3, which withstands heavy abrasion, is used in the Regenerator Cyclones. The SpeedTab® is employed for edges and corners.

More: SpeedSeriesFor the Air Grid we use the Fiberfix system, SpeedHex®3 or SpeedTabs. Depending on the application.

More: SpeedSeriesSpeedHex®3, which withstands heavy abrasion, is used in the Reactor Cyclones. The SpeedTab® is employed for edges and corners.

SpeedSeriesThe SpeedHex®3 , which resists heavy abrasion, is used in the stripper (or filter)

SpeedSeriesIn the dynamic world of the petrochemical industry, where intricate installations define the landscape, your operations demand nothing less than the pinnacle of cutting-edge technology and exceptional service.

Turnarounds hold the key to your plant's continuous success, but these essential breaks can potentially lead to significant financial setbacks, costing you millions.

This is why meticulous planning, rapid yet reliable execution, and a seamless repair process are at the heart of our approach.

Our sole focus is on getting your plant back up and running swiftly, ensuring minimal disruption and maximum value for you.

Crafted by SILICON's experts, RAW technology stands as a groundbreaking technique for affixing refractory anchors within high-temperature vessels and furnaces. Renowned across the industry, this method revolutionizes anchor installation, enhancing every facet of quality, speed, and safety.

Reduce Turnaround downtime

Improved lifetime of your refractory linings

Reachable 24/7 in case of emergency

Easier scheduling – more disciplines can work alongside the RAW team

Pre-turnaround service with discovery work

SILICON Quality Control Technicians for contracting companies

Problem solving solution partner

Quick mobilization of RAW machines, guns, anchors and welding teams during emergencies

We know that it is crucial for our customers to minimize downtime on their plants and projects.

That’s why we make every effort to ensure our service delivery is geared to achieve that goal.