SILICON pushes the limits of Refractory Anchoring Technology in the cement industry with our innovative design and alloy choices to overcome the most aggressive corrosion and strength conditions.

Every step within the cement production journey presents distinct challenges to the refractory lining. Your choice of raw materials, the fuel utilized, and the specific design and operational traits of your kiln all shape the refractory options you consider. At every juncture of this process, we provide customized solutions that align precisely with your requirements.

Continual demands made on the cement industry for greater productivity and lower maintenance costs have pushed the industry to the limits of the conventional technologies existing on the market today.

Most common problems are the result of poor-quality anchoring systems and include:

Corrosion

Chemical attacks

Detachment of anchors and/or refractory concrete

Low-quality welds

These problems can lead to urgent repairs, costing cement plants time and money.

SILICON has recognized many of these issues and offers the following services to the cement industry:

Solutions beyond ‘what was thought possible’

Advanced technological support to ensure our customers a cost-effective future

Solutions that drastically reduce Turnaround time thanks to our Rapid Arc Welding (RAW) technology

A solution for welding in difficult-to-reach places

The SpeedSeries® system that delivers a positive return on investment

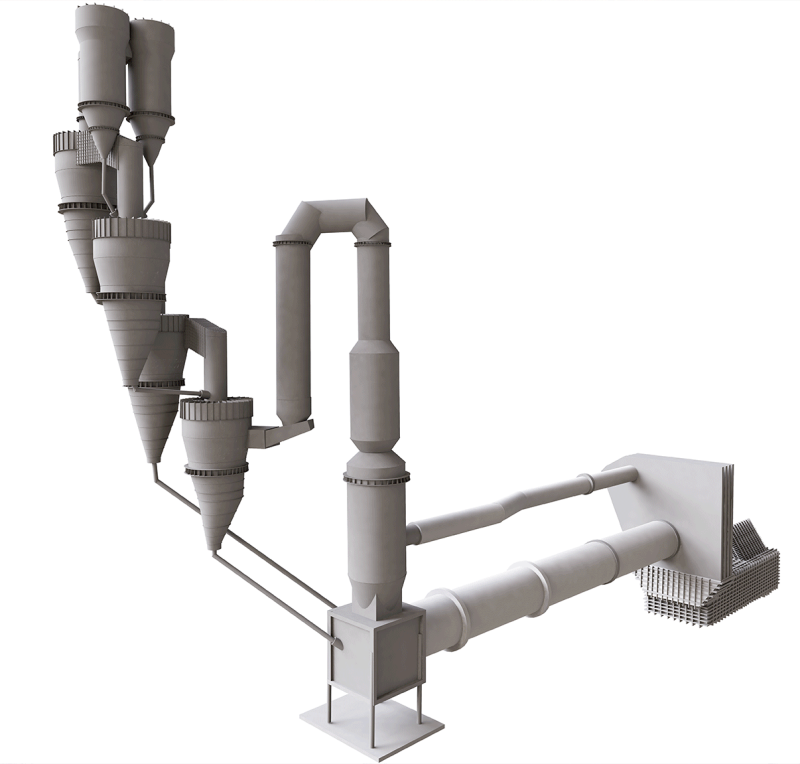

We offer refractory anchor solutions for rotary kilns, upper and lower cyclones, coolers, burner pipes, pre-heaters, air ducts, and calciners because we know each process has its own unique problems.

Click on the various components for more information.

In Pre-Heater Cyclones, the SpeedBolt® System can last 10+ years. Find out more about this moveable system:

C-10 Moveable anchors (SpeedBolt®)The SpeedBolt® system is used in Cyclones, which can last 10+ years. Find out more about this moveable system:

C-10 Moveable anchors (SpeedBolt®)Brick claws are used in the Calciner. SILICON has created the RAW weldable SpeedClaw. Find out more about this system:

B-03 Brick ClawsStress often arises in Rotary Kilns due to refractory movement. Explore the SILICON moveable SpeedBolt® System here to address this issue.

C-10 Moveable anchors (SpeedBolt®)Burner pipes see a lot of corrosion due to the intense heating process, the SILICON SpeedCell® solved this. Find out more:

C-11 SpeedCell®In the cooler, the SILICON SpeedBolt® system is used, which is a moveable anchoring system. Find out more about this solution:

C-10 Moveable anchors (SpeedBolt®)SpeedCell® systems transcend boundaries, providing remarkably adaptable solutions for various refractory anchoring needs.

Ideal for areas prone to rapid refractory wear due to severe abrasion

Burners will last two or three times longer

The single point fastening method, using a stud, allows for safe and damage-free repetitive expansion and contraction of the refractory material

Installed with Rapid Arc Welding (RAW) Technology

Strong refractory holding power

Studs available in any alloy

The SpeedBolt® is a combination of incredibly fast installation of both the anchor itself and the floating system.

Stainless steel

Withstands corrosion

Prolonged lifespan spanning multiple Turnarounds

Sustainable and enduring solution

Quick installation with RAW technology

Tired of the manual welding of Brick Claws? Embrace efficiency with SILICON’s SpeedClaw!

Uniform brick-weight distribution over the anchor's head

Robust

Highly resistant to corrosion

One-stud solution

Installed 10x faster with our RAW technology

When it comes to designing, manufacturing, and installing refractory anchors in the cement industry, we are the experts.

It is crucial for our customers to minimize downtown, and that is why we make every effort to ensure our service delivery is geared to achieving that goal.