This month, on the 3rd of November 2024, we celebrated the birth of SpeedHex® 3, a one-of-a-kind anchor that transformed the refractory industry globally.

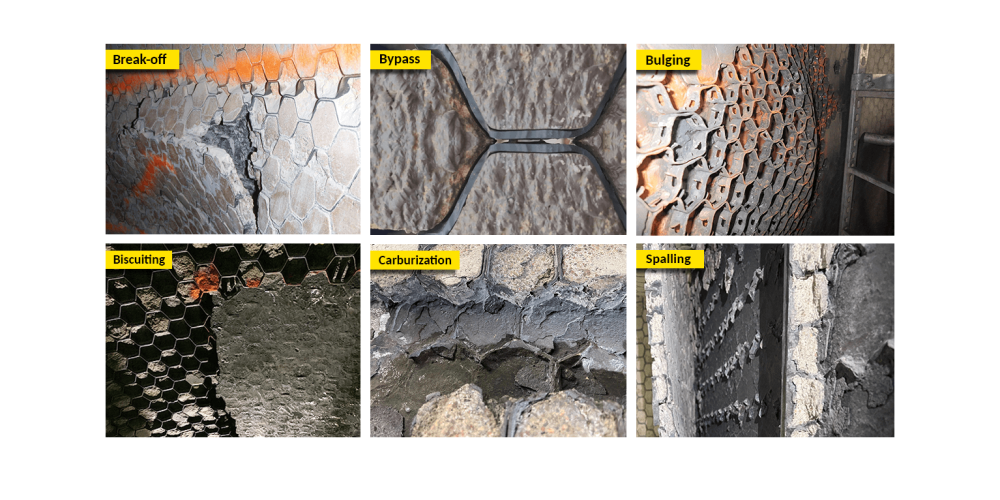

New ideas often arise from the practical needs of real-world industries and applications. Industry experts are aware that hex mesh can cause unexpected shutdowns, leading to production losses of up to 10-15% and increasing operational downtime by 20-30% due to repair time.

A solution to the hex mesh problem sparked the need for a new approach - an anchor that promises a more reliable fit and enhanced stability. SpeedHex® 3 was designed to tackle these issues head-on.

As 2013 unfolded, SpeedHex® 3 was starting to take shape. It was a year of experimentation for the Engineering department. By early in 2014, SILICON had the prototype. Fueled by questions and answers, SpeedHex® 3 gradually morphed from an abstract idea into a reality! This design offered enhanced stability and durability, setting a new standard in anchoring systems in petrochemical industry.

“The SpeedHex® 3 concept evolved into a completely new system design, including innovative welding methods and accessories. By the end of 2014, the first installation took place, and by the end of 2024, it was an immediate success,”

Danielle Garot, Head of Engineering

SpeedHex® 3 filled a critical gap in the industry, addressing pain points that had lingered for years. The SILICON team of engineers developed a product that not only meets but surpasses industry standards. Since its launch, users’ feedback has been overwhelmingly positive, highlighting its ease of use and adaptability in the most challenging applications and extreme environments.

“The simplicity of the installation process for SpeedHex® 3 ensures both speed and accuracy. When combined with the advanced technology of the SILICON welding machine and high-quality refractory materials, the anchor’s performance is remarkable. I've personally witnessed inspectors and industry veterans do double takes, as anchors still appear brand new even after two or three runs.”

Sam Warden, Commercial Project Manager

Stop Struggling with Hex Metal Installation – Meet SpeedHex® 3!

Traditional hex metal installation is time-consuming, inconsistent, and requires tedious prep work like cutting and manual fitting. Say goodbye to these hassles with SILICON's game-changing SpeedHex® 3 and Rapid Arc Welding —

the ultimate solution for all your hex metal challenges!

SpeedHex® 3 received high praise for its qualities and features. The SpeedHex® 3 system proved to be advanced, as it protects your refractory, a goal no other product can achieve.

Designed as a natural evolution to the original hand-welded hex metal, SpeedHex® 3 has had a significant impact since its introduction. Here are its Proven benefits:

It provides the strongest hold and most reliable performance.

It is designed for extended use, eliminating the need for frequent replacements.

It is built for ultra-intense environments.

“The SpeedHex3® is really fast to install :

implementing this technology made T&I Teams save costly hours of the shutdown planning.”

Total Harfleur

Explore our success stories and discover how SpeedHex® 3 along with our Rapid Arc Welding technology can revolutionize your Turnaround: