Hiring the wrong company to handle your emergency can exacerbate your critical shutdown, turning it into a secondary emergency that requires additional resources to resolve. Emergency shutdowns can be incredibly costly, with a single day of downtime in an FCC unit potentially costing more than seven million dollars.

In such high-stakes situations, relying on hex mesh or hand-welding anchors is not a viable solution due to its slow installation process. When dealing with confined spaces, difficult areas, corners, and curved surfaces, the optimal solution is SILICON refractory anchors. These anchors are designed to provide a quick and effective response, ensuring that all areas, no matter how challenging, are adequately addressed.

Evaluate the Emergency and Unplanned Turnarounds by determining its nature, the extent of the failure, and the available time.

Facing a disaster? Time is running out, and the team can already foresee the budget loss if the repair isn't completed today. Our global Emergency Response Team, with decades of experience, and Rapid Arc Welding (RAW) solution are here to help.

Contact the SILICON Emergency Crew, available 24/7. You can reach us by email at raw.projects@silicon.nu or via the contact page at www.silicon.nu/contact

Provide details about the failure, including scope, anchor types and quantity, number of RAW machines, and crew size. If unsure, our experts are ready to assist and advise.

With offices in the USA, the Netherlands, and Japan, and a worldwide partners network, we can respond immediately.

Once we receive your inquiry, our Sales Managers will promptly provide anchor and service quotes. Our Project Team will then arrange the mobilization of the crew and equipment to ensure a swift response.

Revolutionary SpeedSeries refractory anchors are the usual picks of Turnaround Managers in times of emergency.

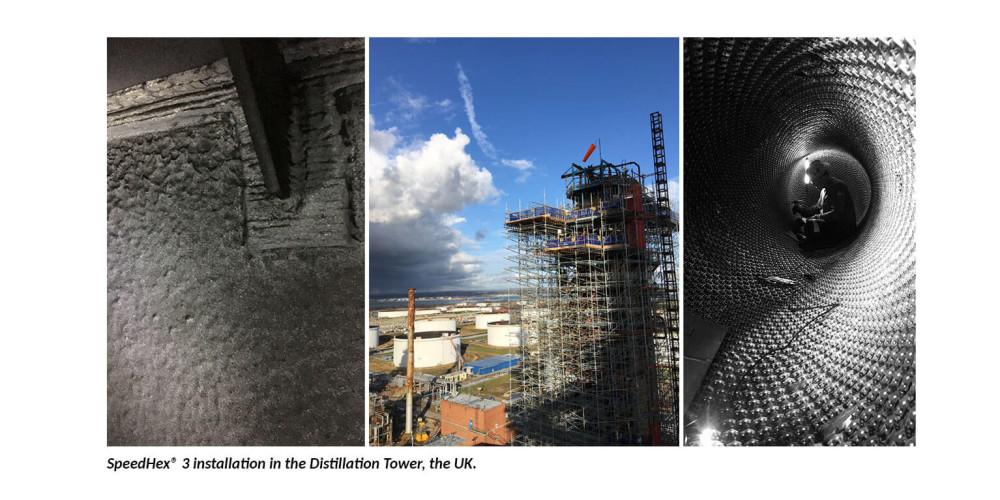

SpeedHex® 3

Alternative to hex metal. SpeedHex®3 prevents detachment of refractory from the shell by ensuring continuous protection and superior welds.

SpeedTab®

SpeedTab® provides greater refractory protection and resolves termination bar issues on corners where standard tabs fail.

SpeedVee®

Alternative for hand-weldable V anchors. SpeedVee® anchors outperform conventional V anchors by providing mechanical upgrades with full fusion welds.

Safe. Cost-effective. Quick - up to 1200 welds per person per day.

No overheating. No power loss. Easy access to the tightest spots of your unit.

RAW machines regulate each part of the welding process using a computerized system to drive the motion of the welding gun and energy input. Our technology compensates for power loss that usually depends on cable length, eliminating the need to move machines from one level to another. Simply use one of the longest cables, as we do in our projects.

D36 – Dual gun machine, for studs up to 36mm

D24 – Dual gun machine, for studs up to 24mm

D20 – Dual gun machine, for studs up to 20mm – the top choice for Turnaround Managers worldwide due to its exceptional capabilities.

S16 - Single gun-portable machine, for studs up to 16mm

PS12 – Single gun-portable machine, for studs up to 12mm

PUM50 – a small and versatile gun that can reach into even the tightest corners, 3 – 19 mm.

PNG50 – comfortable and durable to use, this is our most popular gun, 3 – 19 mm.

PNH70/120 – most powerful gun, suited for heavy anchors, 3 - 36mm.

Adapters (Limited Space Adapters, Gun Nose Extenders, Footplate Extenders)

Footplates

Chucks (stud holders)

Ferrules

Cables and connectors (Ground and gun extension cables, plus connectors)

Whether it's adapting hand welding specifications to Rapid Arc Weldable standards, re-engineering custom-designed anchors and chucks according to your blueprints, or getting them annealed, we have mastered it all for any emergency scenario you might have.

Once the order is placed, the SILICON crew will prepare for mobilization. Upon arrival, our team will immediately start an Emergency Response Intervention.

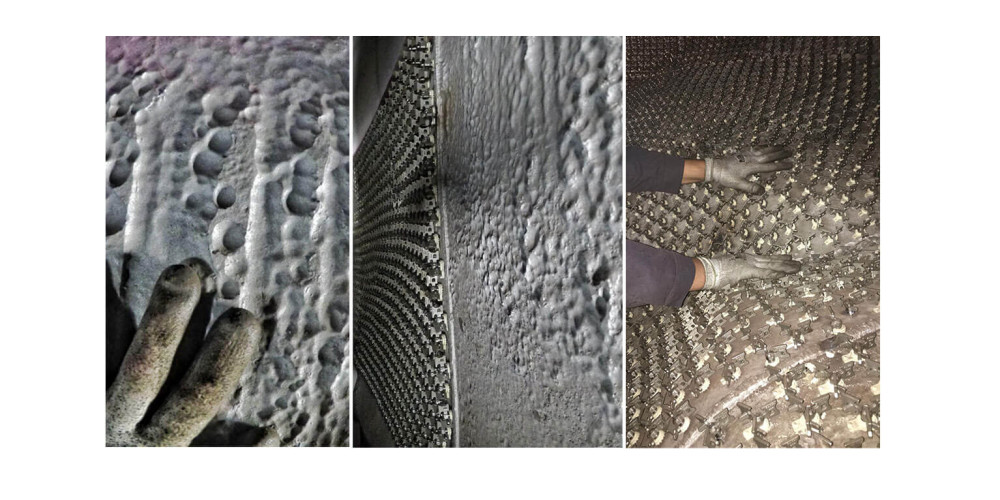

We can perform work on almost any surface.

Surfaces:

SILICON RAW machines adapt to the most difficult surfaces and welding conditions, ensuring a perfect weld every time, no matter how curved the surface is. There is no guessing with the SILICON gun; a welding operator can verify the weld by looking at the LED light. If the green light is on, the weld is successful.

One of our teams recently returned from an inspection of the distillation tower in France. Seven years ago, there was an explosion, and the SILICON team had an emergency mobilization to install SpeedHex® 3.

The inspection revealed that SpeedHex® 3 has been providing robust protection to the unit, shining strong after seven years in service.

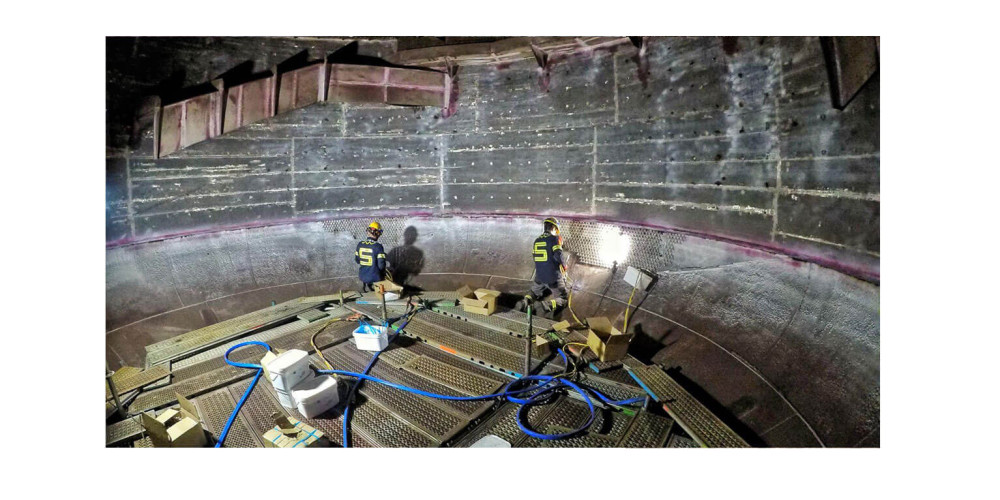

Tight Spaces and Corners:

We can complete work even behind obstructions like scaffolds and metal beams. Our technology prevents the welding gun from collision in the most challenging spots, even in units with limited space behind the gun.

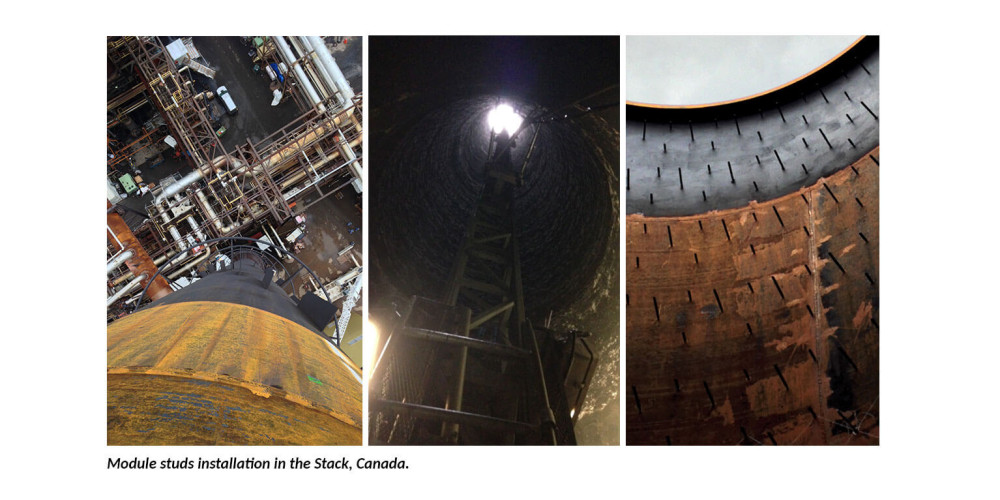

Units:

Complicated work at Heights, Plenum of the Burner, Distillation Tower, Refinery Stack? You name it, we get there.

With your operation back on track, it's time to demobilize the SILICON crew. Simply notify the Project Team about the completion, and we will handle the rest.

Emergency Now? Our RAW Crew, machines and refractory anchors are ready!

Ensure your business stays resilient by reaching out to us for any future needs. If you believe your partners or customers could benefit from SILICON Emergency Response, please share this article with them!