An interview with Damian Wawrzyniak, SILICON Global Shipbuilding Expert.

We sat down with Damian Wawrzyniak, SILICON’s Global Shipbuilding Expert, to discuss the company’s approach to supporting the maritime industry, challenges in modern shipbuilding, and how innovation is reshaping the way ships are built.

Damian Wawrzyniak (A): I got into shipbuilding in 2019, visiting yards across Europe and later in the U.S. What got me hooked was the openness to innovation and the chance to work closely with welders, engineers, and supervisors. It’s not just about technology, it’s about solving real challenges with real people.

Damian Wawrzyniak (A): I think the shipyards that succeed are the ones where teams work closely, stay open to new ideas, and keep improving together. This is the foundation.

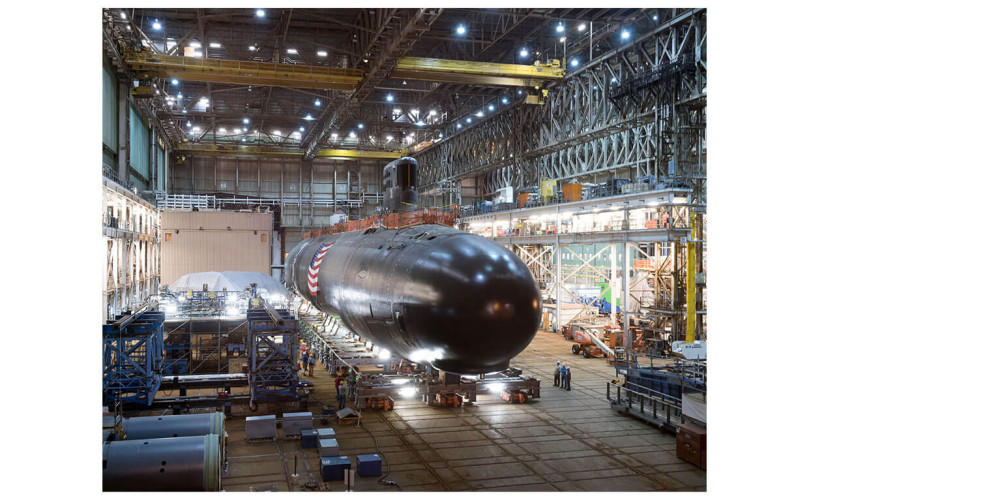

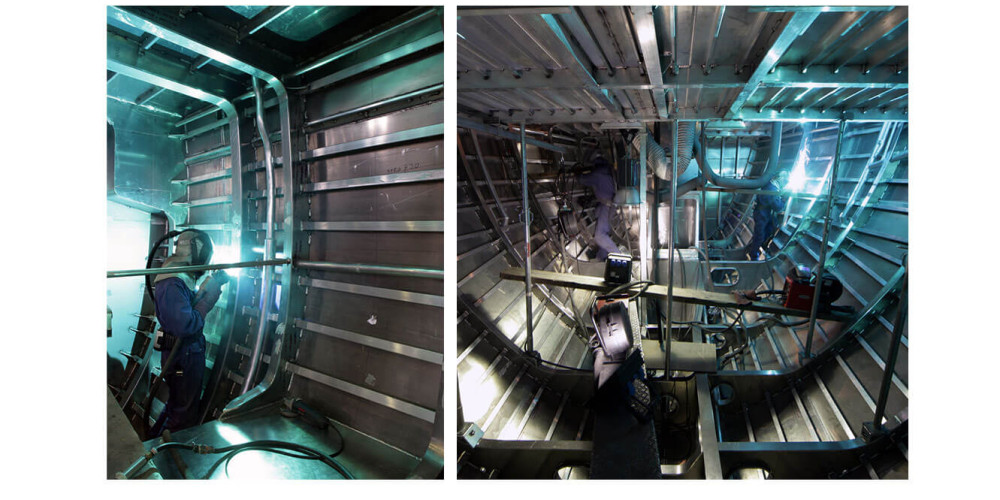

Damian Wawrzyniak (A): Manual welding, inconsistent quality, and tricky access are common issues. Leading yards are switching to automated systems and tailored components to speed things up and improve reliability.

Damian Wawrzyniak (A): The key ones are welds per hour, first-pass yield, rework rate, and equipment uptime. What’s interesting is that with SILICON’s solutions, yards shift from just counting manual output to focusing on precision and consistency. These KPIs become a lot more useful when machines are doing the heavy lifting, it’s all about being smarter, not harder.

Damian Wawrzyniak (A): They’re teaming up with full-solution suppliers, switching to RAW for faster results, and using portable machines to improve quality in tight spaces.

Damian Wawrzyniak (A): What I see is a smart blend of old and new. They’re not throwing out their traditional methods, instead, they’re bringing in advanced welding techniques and digital design tools that fit right alongside what’s always worked. It’s about using technology to make things better, but never losing sight of the craftsmanship and standards that define shipbuilding.

Damian Wawrzyniak (A): I’d say start by looking at advanced welding technologies, especially Rapid Arc Welding (RAW). It’s not just about chasing the latest trend. RAW is straightforward to use, and crews pick it up quickly. You get better weld quality and efficiency right out of the gate, without needing to overhaul everything at once. It’s a practical move that makes a real difference on the shop floor, and it sets you up for bigger improvements down the line.

Damian Wawrzyniak (A): In short, digitalization helps shipyards keep welds consistent by saving all the right settings in the RAW machines. It also spots weak welds or mistakes instantly, so crews spend less time fixing things, and tracks weld data to help teams continuously improve how they work.

Damian Wawrzyniak (A): Quality-wise, RAW raises the bar. You get strong, consistent welds for studs and fasteners, so there’s less worrying about mistakes or weak spots. And because the process is so much faster, shipyards are seeing fastening and assembly operations speed up by as much as 50%. That means projects move along quicker, but you’re not sacrificing quality to get there.

Damian Wawrzyniak (A): Definitely. With SILICON Total Solutions, shipyards get more than just digitalized RAW machines, they also receive OEM studs and ferrules that are specifically designed to work seamlessly with our equipment. That means fewer misfires, less downtime, and smoother operations overall. Plus, we offer global onsite support and hands-on training for operators, so crews feel confident and work more efficiently from day one.

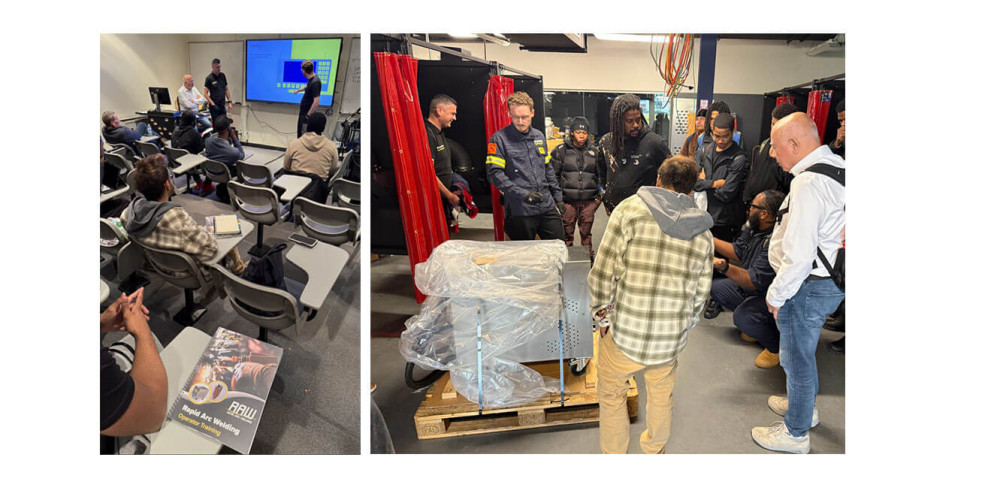

Damian Wawrzyniak (A): It’s a mix of theory and hands-on practice. We make sure teams understand how the equipment works, then we guide them through real production scenarios on-site. That way, operators feel confident using the machines and can keep welding quality consistent, even across different shifts or tough conditions.

Damian Wawrzyniak (A): We offer online support, in-house workshops, and on-site training. There’s online support and troubleshooting for quick help, but the real value comes from our hands-on training. We run a one-day workshop that covers both the theoretical and practical use of RAW equipment, where trainees get to operate the machines with guidance from our experienced trainers. Then we spend two more days on-site, working directly with the teams during live production. That’s where we help fine-tune workflows and solve real-world challenges. Trainees learn how to troubleshoot problems, so they gain confidence and can avoid these mistakes in real production.

Damian Wawrzyniak (A): Consistency starts with saving the right welding parameters directly in the machine, supervisors can lock in programs, so every operator is working with the same settings. On top of that, SILICON machines log every weld in real time. That gives trainers and supervisors a clear view of performance, helps spot issues early, and allows for quick coaching. It’s a smart way to keep quality high and learning fast.

Damian Wawrzyniak (A): It really depends on the size and needs of the shipyard. For many, we run a recurring program where our trainers visit the shipyards every three months.

Damian Wawrzyniak (A): Because the training is consistent and recurring, knowledge doesn’t rely on just one experienced welder; it’s shared across the team, so everyone can perform at the same level.

Damian Wawrzyniak (A): Yes, SILICON offers structured training to keep operators’ skills sharp and aligned with industry standards for stud and fastener welding. While we provide onsite training at shipyards and in-house training programs, we also run an official program at the Community College of Philadelphia, supported by the NWI (Naval Welding Institute). This allows students to get familiar with our technology at an early stage. When they complete the program, they receive a formal external certification and are fully qualified and skilled to use RAW systems, so they are ready to work in any shipyard using our technology.

Damian Wawrzyniak (A): Invest in both people and technology. Technology without skilled operators won’t deliver the results you need.